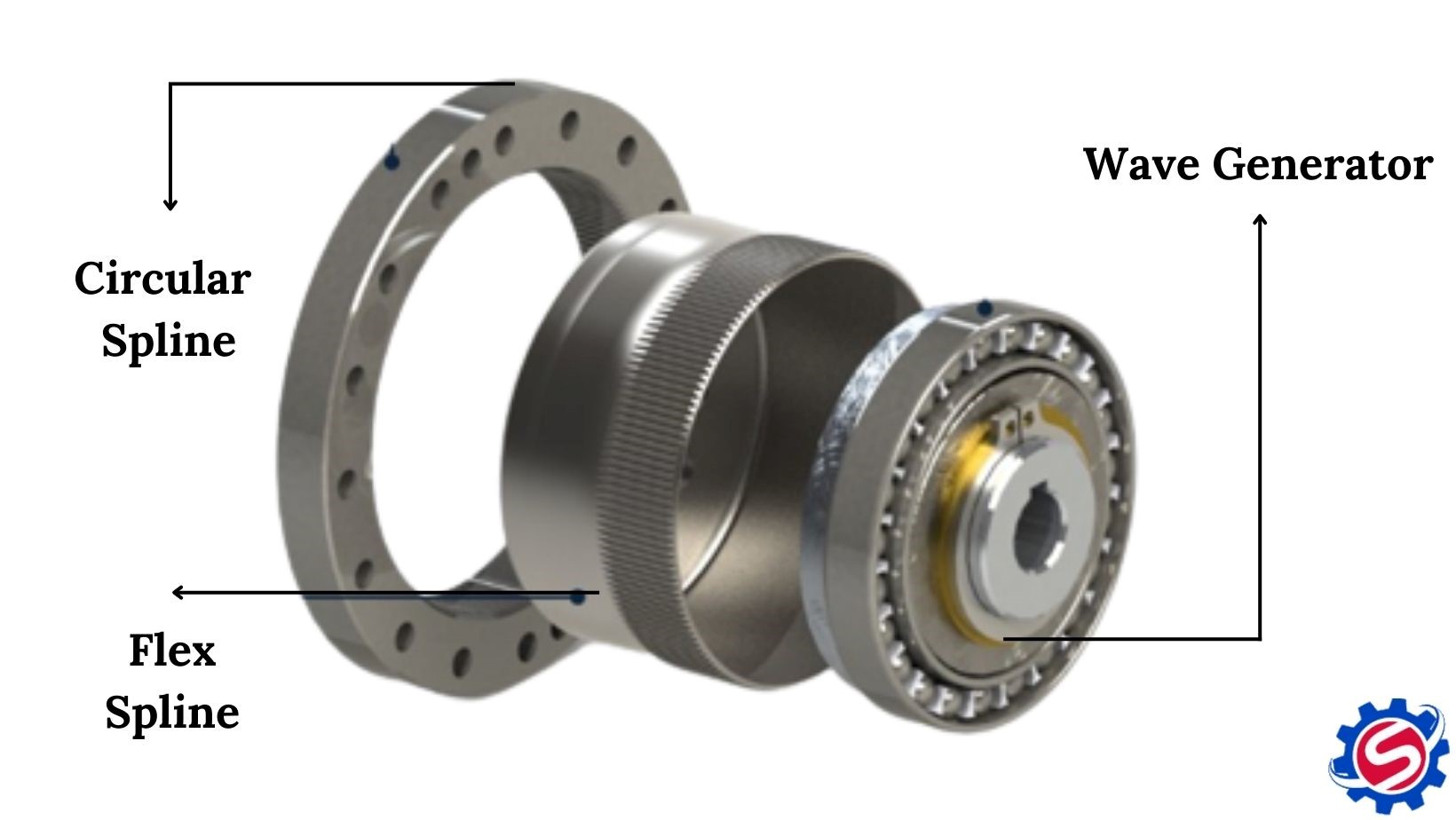

There are 3 basic elements in the Harmonic Drive Gearbox: a circular spline, a flexspline and a wave generator. These 3 components interact in such a way that helps in achieving high reduction ratios.

Wave Generator is an assembly of bearing and a circular disk known as a wave generator plug. The outer surface of this plug has an elliptical shape which is manufactured with the most care. The Ball Bearing which is specifically designed is mounted and pressed around this plug which results in bearing to comply to the shape of elliptical as of wave generator plug. The Wave generator is basically the input of Harmonic Gearbox assembly.

The flex spline is the thin-walled steel cup with teeth machined on the outer surface at the edge of the cup. This cup edge can deflect or be flexible and still remain torsionally stiff enough to transmit motion. The wave generator is inserted inside the flex spline and takes the shape of an elliptical wave generator disk ring. The flexspline usually works towards the output part of the mechanism.

Circular Spline is the internal gear machined ring and is usually fixed or Rigid ( does not rotate ). The Circular spline has an internal tooth that meshes with the external teeth of flexspline. The flex spline is usually less in diameter than internal gearing and has less teeth than circular spline ( Internal Gear ). The wave generator acts as a link within the two rollers that rotates within the flex spline causing it to mesh with the circular spline progressively at diametrically opposite points. If wave generator rotates clockwise the flexspline will rotate and roll inside the circular spline at a much slower rate in the counter clockwise direction.

The wave generator is rotated by motor which creates a wavelike motion to the flexspline. This results into meshing on external teeth of the flexspline with the internal teeth of circular spline. As the flexspline has two fewer teeth than the circular spline, the tooth disengagement takes place and each revolution of the wave generator causes two tooth displacement of the flexspline in relation to the circular spline. With the help of this mechanism, the Harmonic Reducer acts as a speed reducer. The difference in the teeth of the circular spline and on flex spline results into the ratio of the input speed to the output speed.

Harmonic gearbox is the Most precise gearbox available with the SMD Gearbox series. The Gearbox has a Backlash of upto 12 arc-sec and short axial length which makes our Harmonic series compact and shortest reduction Gearbox for your applications. It is widely used in Robotics and automation Industry where high precision and high accuracy is needed in a limited space.

Visit Our website www.smdgearbox.com for more Blogs and Product Information.

Reference Link - https://www.britannica.com/technology/sawing-machine

PDF Reference Link -

https://web.archive.org/web/20160303211059/http://www.gearproductnews.com/issues/0406/gpn.pdf