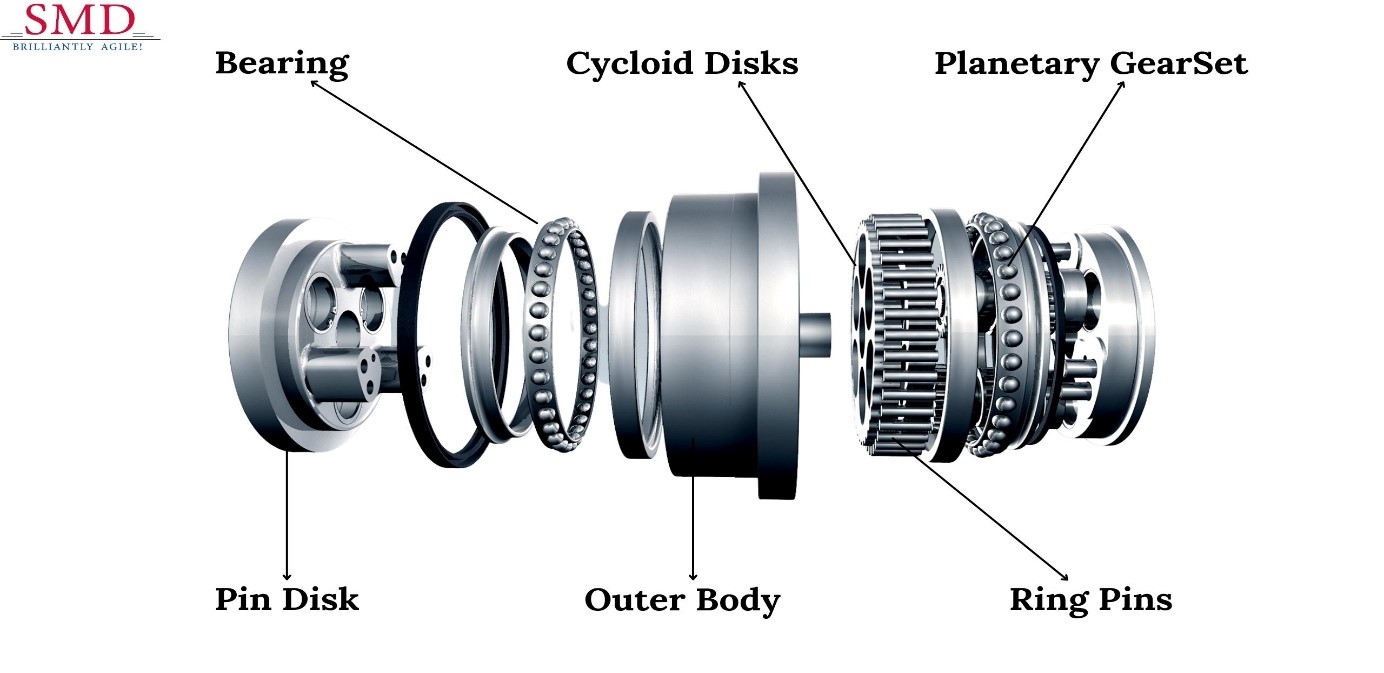

The Cycloidal Gearbox runs on the principle of Cycloidal gears to reduce the speed of the input shaft. The Cycloidal disk is the main component of the Cycloidal gearbox which is driven by an eccentric shaft also called as drive shaft. The Cycloidal disk is engaged with the eccentric shaft where the ring pins are arranged in a circle. The cycloidal disc is driven around these pins by eccentric motion, causing it to revolve around its axis of symmetry. There are holes in the cycloidal disk where the Roller pins of a pin disc engage. These pins move around the hole to achieve steady rotation of the output shaft from the jiggling movement of the cycloidal disc. The Cycloid disk is usually designed to reduce the eccentricity of the disc and unbalance at a high speed thus Cycloidal discs are often mounted offset by 180 degree.

The Ratio of the Cycloidal Gearbox is determined by the number of teeth in the Cycloidal disk and the number of fixed ring pins. The number of teeth must be less than the number of pins on the ring gear, In most cases the cycloidal disc has one lobe ( teeth ) less than the number of pins. Cycloidal Gears are difficult to manufacturer as this Gears requires extreme accuracy in assembly and manufacturing where the gears can sustain capacity to withstand shock loads and less wear on the tooth flanks.

Whenever the application requires high transmission ratios in the compact size two types of Gear are suggested by SMD Gearbox i.e. SMD Planetary Gearbox and SMD Cycloidal Gearbox. The Planetary Gearbox performs on the Planet Gear mechanism where the Sun Gear is fixed, Planet Gear moves around a Sun Gear and the output is received by the carrier. The Rotary axes of the Planetary Gearbox are Planet Gear whereas the rotary axes of the Cycloidal gearbox are Cycloid discs. In comparison with the Planetary Gearbox the Cycloidal gearbox is very rigid against the shock loads and achieves better accuracy and torsional stiffness. Cycloidal Gearbox are more compact than Planetary Gearbox and is used in the Servo Motor applications because of there long service life however, planetary gears usually offer better advantages and higher efficiency, depending on the application.

SMD Cycloidal Gearbox is an ideal solution for a wide range of applications

Robotics – Used in high precision robotics application because of their accuracy and compact size.

Medical and Pharmaceuticals – Used in systems such as CT Scanner and MRI Machines because of their positioning capabilities.

Aerospace – Used in aircraft control systems such as flight control surfaces due to their high accuracy and smooth operation.

Elevators – Used in an Elevator car to provide precise and smooth movement.

Food Processing – Used in Mixers, Grinders because of their high efficiency.

Machine Tool – Used in Machine Tool Industry for lathe and CNC Machines because of high accuracy and smooth applications.

Material Handling – Used in Palletizers and Robot Joints because of its high load carrying capacity.

Sortation System – Used in Sorting systems because of its high accuracy.